จำหน่าย Non-Magnetic Stylus, Point Finder, Tool Setter, Centering Gauge ยี่ห้อ NISSIN จากประเทศญี่ปุ่น

When put a magnet on the table stand of the machine tools,

work is magnetized. And causing measurement errors.

You can high-precision measurement

if you use the non-magnetic stylus (Patent No. 40722822) .

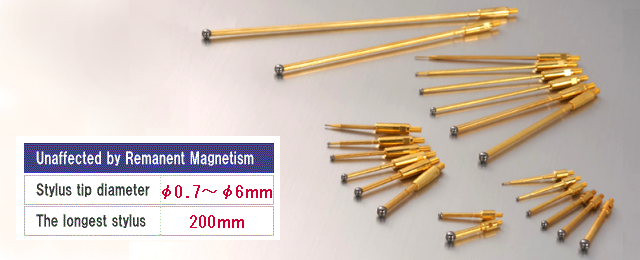

- Features / Remanent Magnetism

- Specifications / Dimensions

10 Biggest Features of the Nonmagnetic Stylus

- No measurement error by magnetic power.

- No need for deGause or replacement of a stylus.

This improves your working efficiency. - Magnetic permeability(μ)≦1.01 … nonmagnetic!

- Sphericity ≦0.6μm

- Hardness: HRA92

- Electrical Resistivity: 3.2μΩ(1/3 of iron)

- Coefficients of linear expansion: 1.2×10⁻6(1/10 of iron)

- It doesn’t rust.

- Special welding method → Low-temperature welding makes a stylus ball difficult

to break and it won’t vary across the ages because of no internal stress. - It has superior quality to others on the market at the same price.

The Influences of Remanent Magnetism with General Stylus

- Features / Measuring Method

- Specifications / Dimensions

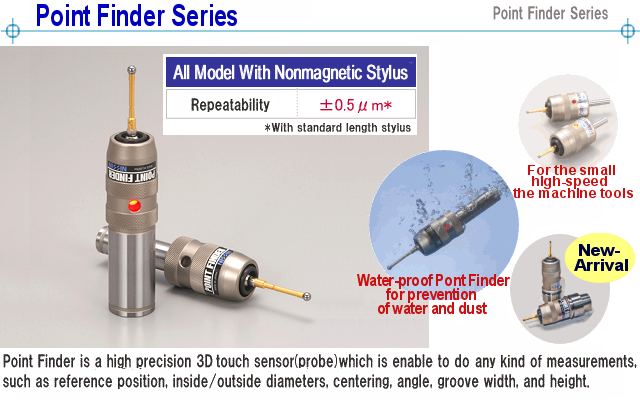

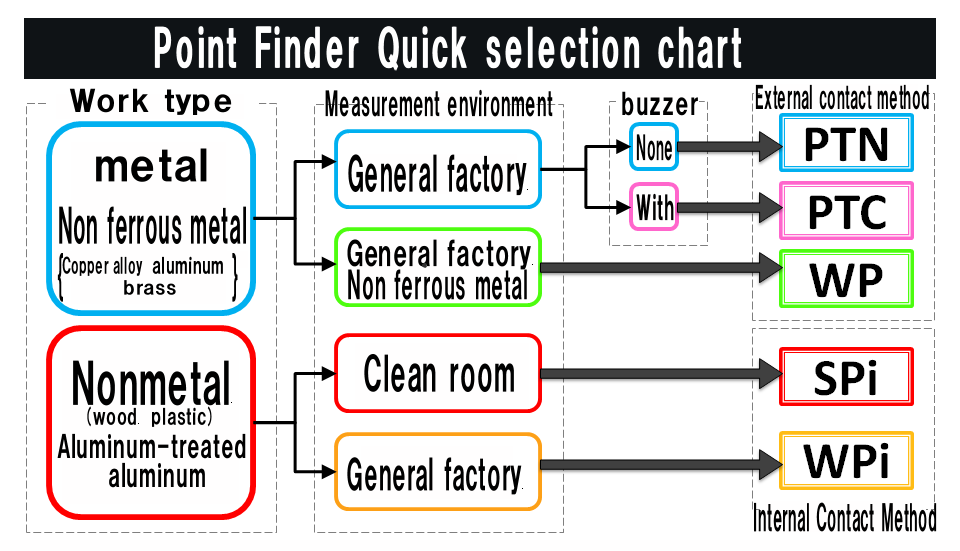

Features of the Point Finder Series

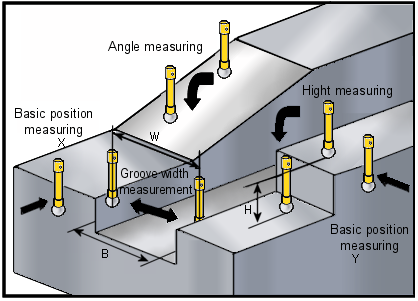

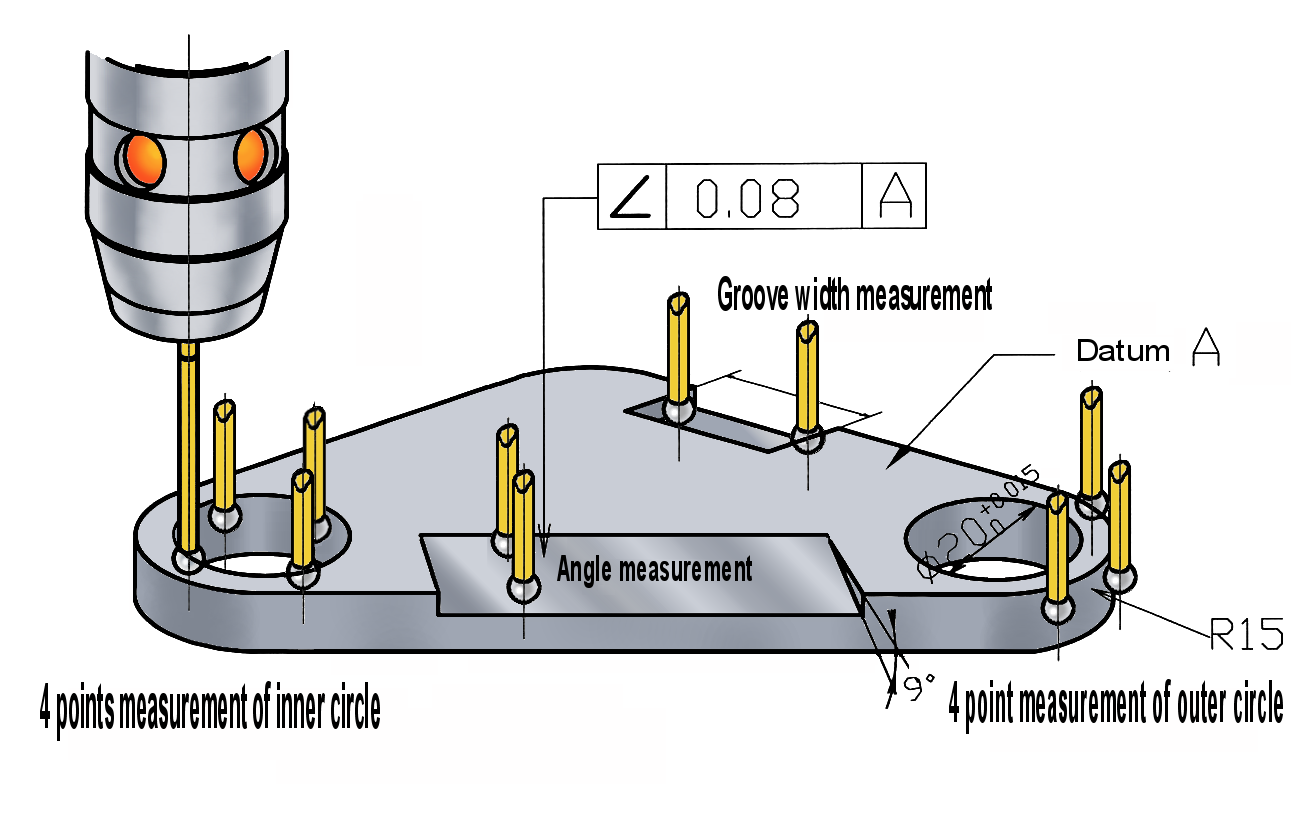

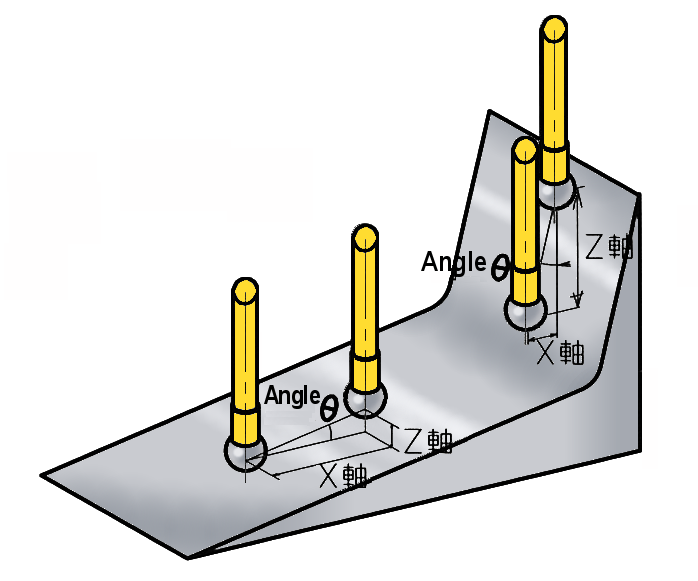

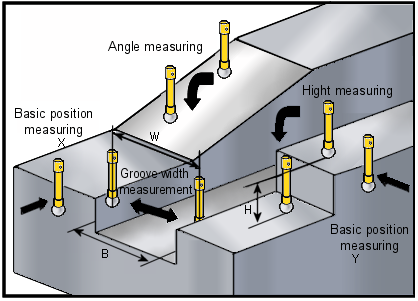

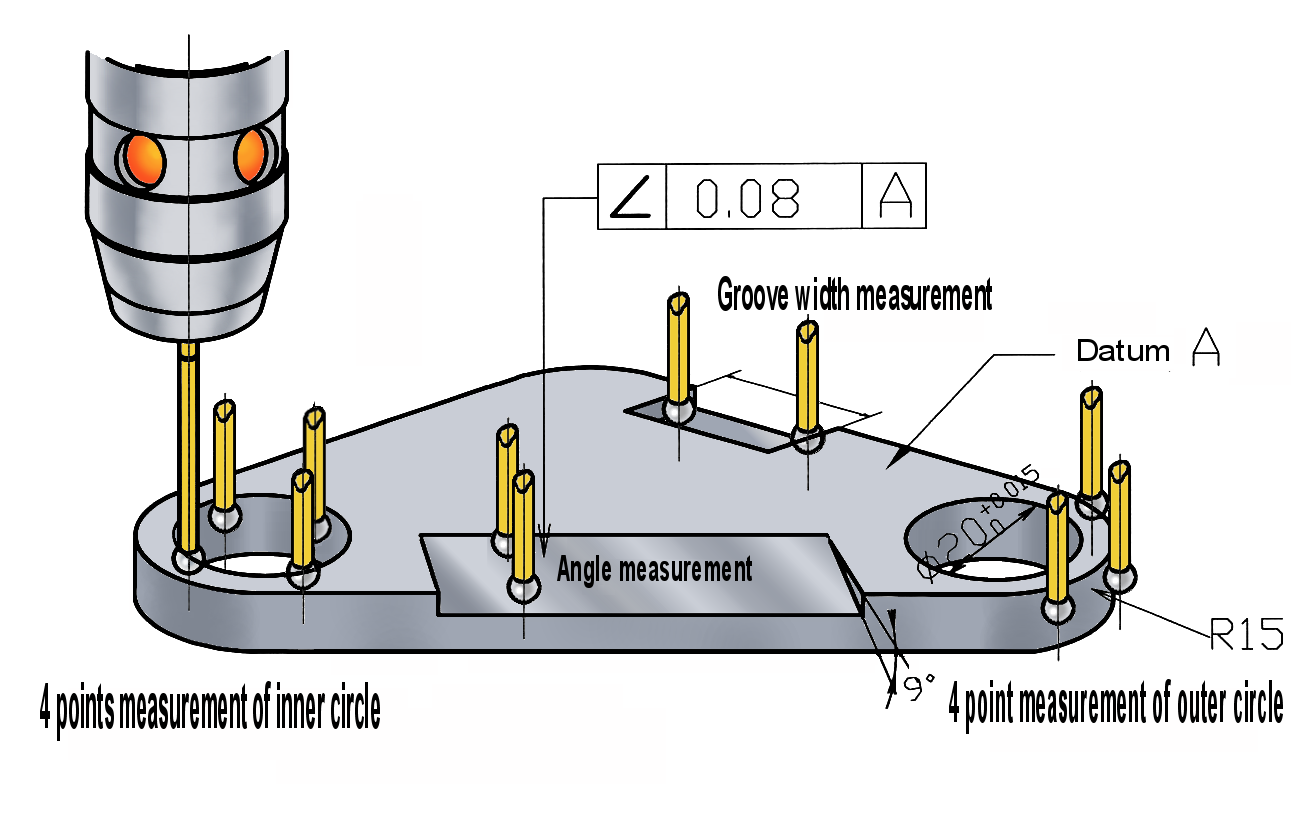

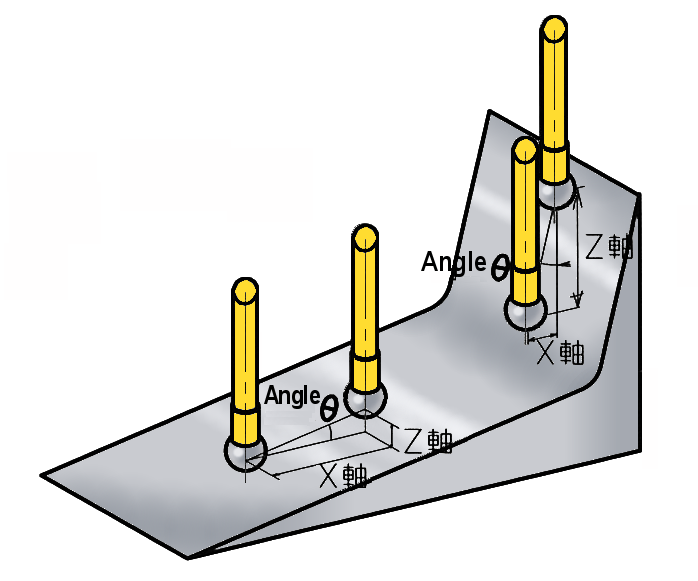

・High precision 3D touch sensor (probe) ‘Point Finder series’ is enable to do any kind of measurements such as reference position, inside/outside diameters, centering, angle, groove width, and height.

For the ultrahigh-precision 3D touch sensor → 【Centering Gauge Swing Type】

・Safety design enables the stylus swing toward X, Y and Z-axes directions and prevents the Point Finder itself from breakage.

・Four LEDs light up when the stylus touches to a workpiece.

・As for PTC (Point finder with a buzzer), three LEDs light up and the buzzer let you know when the stylus touches to a workpiece.

・With nonmagnetic stylus, magnetic force doesn’t affect to the measuring.

→ Check the details of 【Nonmagnetic Stylus】

・Waterproof IP 67 (IEC standard) will not enter water even if it is immersed in 1 m of deep for 30 minutes.

(We use fluororubber for our products, but some cutting fluid contain surfactant dissolves fluororubber, and our company prohibits its use.)

| Point Finder [External Contact Type] |

Point Finder-i [Internal Contact Type] |

|||

|---|---|---|---|---|

| iron, nonferrous metal | Measurable material | metal, nonmetal (plastic, wood…) | ||

| XY-axes | ±11.5mm | Stylus stroke | XY-axes | ±6mm |

| Z-axis | +5mm | Z-axis | +5mm | |

| ±0.5μm (±1μm with the 80mm stylus) |

Repeatability (*1) | ±0.5μm | ||

| XY-axes | 0.001N | Measuring pressure | XY-axes | 0.3N |

| Z-axis | 0.001N | Z-axis | 1.5N | |

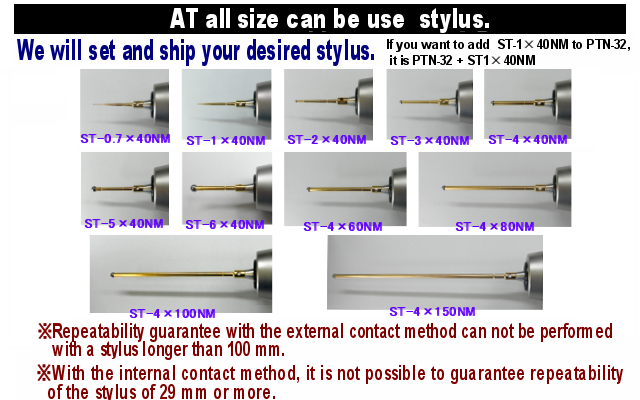

| φ1、φ2、φ3、φ4、φ5、φ6 | Stylus tip diameter | φ2、φ3、φ6 | ||

| ST-4×40NM(*2) | Standard stylus | ST-6×29NM(*2) | ||

| PTC series has a buzzer | Other feature | available to MC with a ceramic spindle | ||

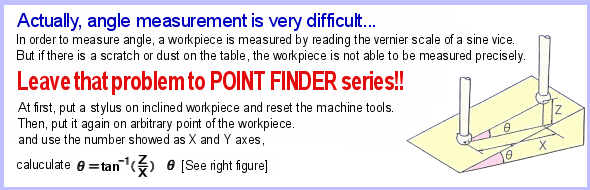

How to Measure

*tan-1tan-1 is called undertangent.

Please calculate it with a calculator or use a smartphone calculation application.

↓ <*Document>The permeability measurement data of the nonmagnetic stylus is here. ↓

Permeability measurement report

Permeability measurement report

Permeability measurement data

Permeability measurement data

Repeatedly even with a 150mm stylus length accuracy ± 1μm guarantee (Patent No. 5133884)

25 fiscal year, Chubu Regional Development Award [Invention Award] award

- Features / Measuring Method

- Specifications / Dimensions

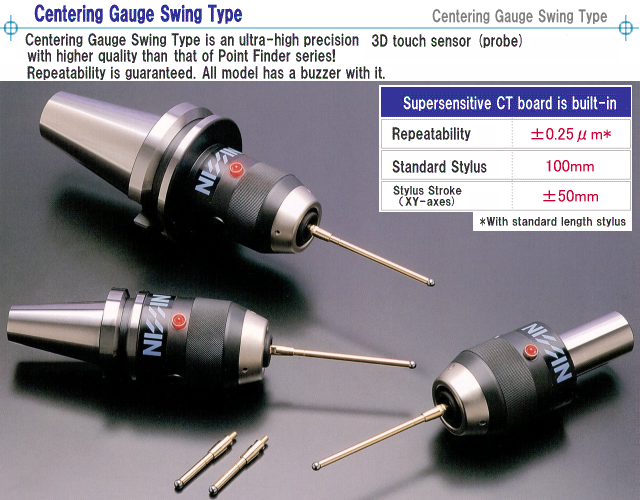

Features of the Centering Gauge Swing Type

- Centering Gauge Swing Type is the ultra-high precision 3D touch sensor (probe) with higher quality than that of Point Finder series.

Use it for all kinds of measurements such as for reference position, inside/outside diameters, centering, angle, groove width, and height. - Supersensitive CT board is built-in the Centering Gauge Swing Type and it doesn’t cause ‘Chattering’ phenomenon.

※Chattering: When the stylus touches to a workpiece, the LED flashes on and off

because of the variation of both voltage and current occured by electrical resistance. - Thin workpiece is measurable because the contact pressure between the stylus and workpiece is lower.

- It doesn’t cause the triangle error.

- Iron and nonferrous metal materials are measurable. It’s unaffected by oil film.

Use “Point Finder-i” [Internal Contact Type] for measuring metal and nonmetal materials such as plastic, wood, etc. →【Point Finder series】 - Safety design enables the stylus swing toward X, Y and Z-axes directions and prevents the Centering Gauge Swing Type itself from breakage. Especially, swing width toward X and Y-axis is ±50mm !

- All models have a buzzer. It beeps at the very same time when the stylus touches a workpiece and the LED emits.

- With nonmagnetic stylus, magnetic force doesn’t affect to the measuring.

→ Check the detail of 【Nonmagnetic Stylus】 - Customized model with a connector (but no CT board) can take information as an external trigger code. However, the code is read out as analog signals, so it’s neccesary to translate the analog signals into the digital ones.

Comparison between Swing Type and Point Finder [External]

| Centering Gauge Swing Type | Point Finder [External] | |||

|---|---|---|---|---|

| iron, nonferrous metal | Measurable Material | iron, nonferrous metal | ||

| XY-axes | ±50mm | Stylus Stroke | XY-axes | ±11.5mm |

| Z-axis | +10mm | Z-axis | +5mm | |

| ±0.25μm | Rpeatability(*1) | ±0.5μm (±1μm with the 80mm stylus) |

||

| XY-axes | 0.0001N | Measuring Pressure | XY-axes | 0.001N |

| Z-axis | 0.0001N | Z-axis | 0.001N | |

| φ1、φ2、φ3、φ4、φ5、φ6 | Stylus Tip Diameter | φ1、φ2、φ3、φ4、φ5、φ6 | ||

| ST-6×100N(*2) | Standard Stylus | ST-6×40NM(*2) | ||

How to measure

i-50 is improved accuracy repeatedly in the adoption of Patent No. 5133884.

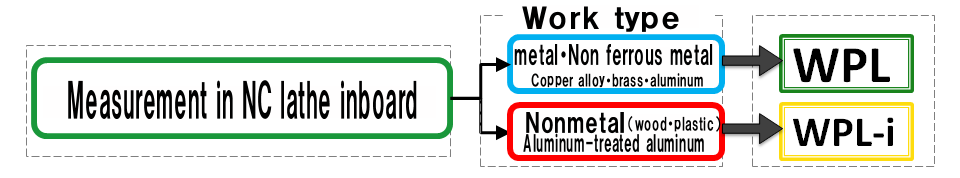

- Features / Measuring Method

- Specifications / Dimensions

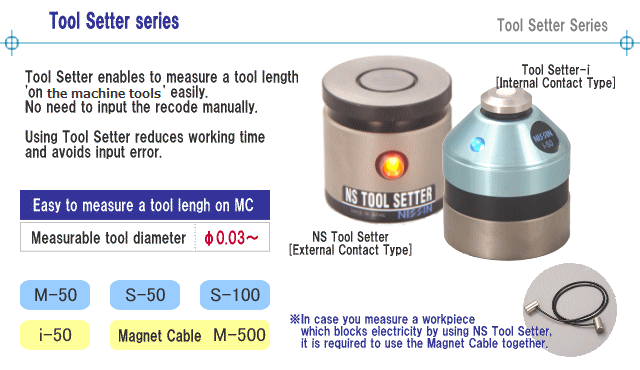

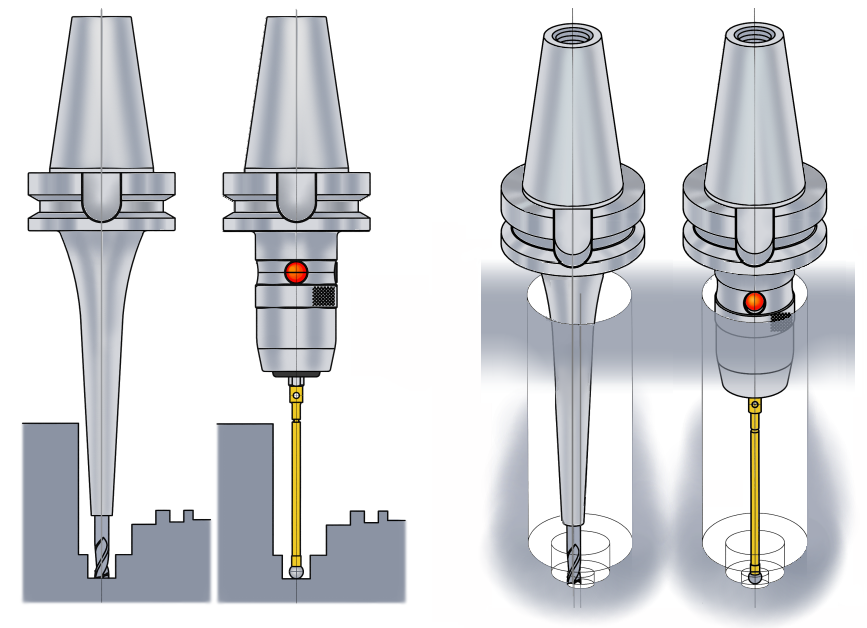

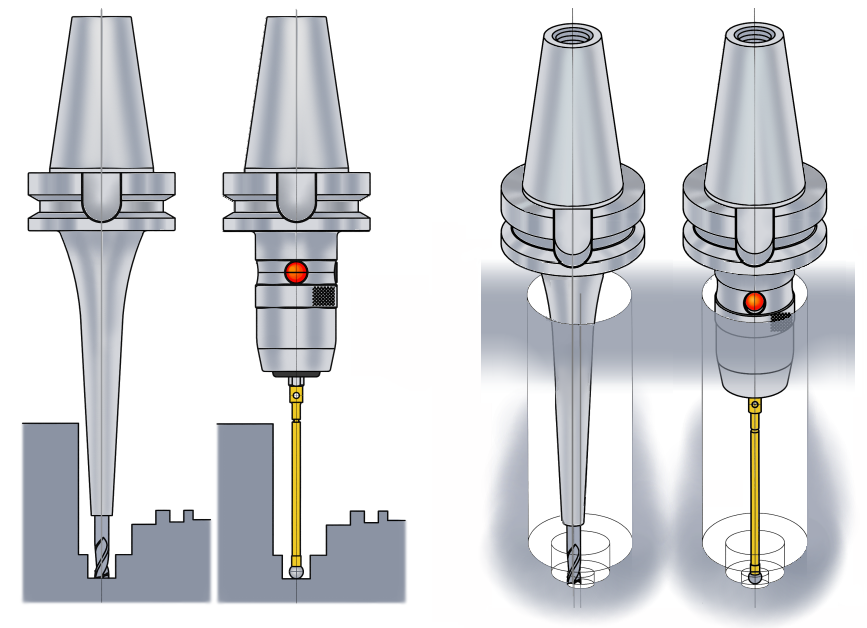

Features of the Tool Setter series

- NS Tool Setter makes it possible to measure the tool length (the position of a drill tip) on the machine tools. It saves your machining time!

- Sub-zero treatment and ultraprecise polish prevent the variation across the ages.

- It is usable to measure iron and nonferrous metal workpieces.

- Tool Setter-i has been developed for ultra-highspeed spindle with the machine tools (10000rpm).

- It is available to measure plastic, wood and some other materials which block electricity.

- Magnets are attached at the bottom, so it can be used with both vertical and holizontal machining tools.

| NS Tool Setter [External Contact Structure] |

Tool Setter-i [Internal Contact Structure] |

|

|---|---|---|

| iron, nonferrous metal | Measurable Material | metal, nonmetal (plastic, wood…) |

| 5mm | Vertical Stroke | 1.5mm |

| ±0.001mm | Repeatability | ±0.001mm |

| 0.001N | Measuring Pressure | 0.2N |

| 6N | Magnetism | 6N |

How to measure the tool length with the Tool Setter

Input error is one of the causes of runaway accident.

Let the automatic input in the tool setter.

- Features / Measuring Method

- Specifications / Dimensions

Features of Centering Gauge

- Easy and high-precise centering is possible just to put Centering Gauge on the MC spindle and bring it into contact with a workpiece.

- Available to any kind of metals.

- Measurements of inside/outside diameters, depth, circle/hole size, and of course, centering are all clear with Centering Gauge.

- Concentricity of axle and shank is within 3/1000mm, thus it is also available as a test bar.

- Centering Gauge with nonmagnetic stylus prevents to attach the machining swarf and doesn’t affect measurement.

How to measure with Centering Gauge

For measuring angles, use 【Point Finder series】.

Credit : http://www.nissinsan.jp